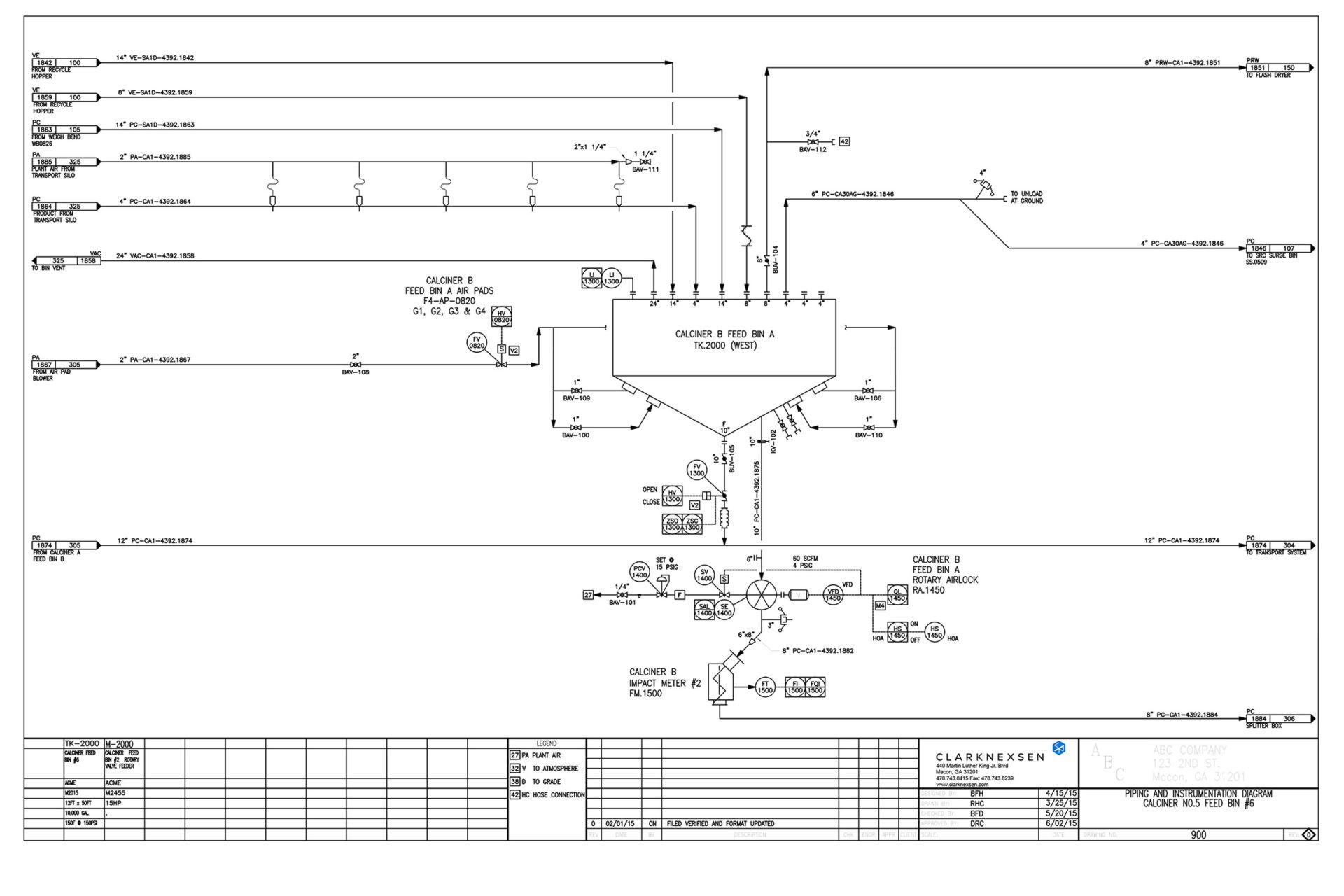

Our team of process engineers and automation specialists leverages CAD technology for P&IDs that creates a ‘smart’ P&ID, linking to a SQL database that provides a record of extensive data including horsepower, supplier, equipment specs, and more.

As manufacturing companies grow and processes shift, their manufacturing facilities must expand and adapt to meet new needs. Without a ‘roap map’ – or in this case, a plantwide piping and instrumentation diagram (P&ID) – the design process for expansions and manufacturing line changes can be made much more challenging and less efficient. Clark Nexsen’s industrial design team has established a strong partnership with a confidential client at facilities in the Southeast and is working with plant managers throughout Georgia to meet this need by developing comprehensive, up-to-date piping and instrumentation diagrams and implementing a process to ensure these drawings remain current and accurate into the future.

Our team of process engineers and automation specialists leverages CAD technology for P&IDs that creates a ‘smart’ P&ID, linking to a SQL database that provides a record of extensive data including horsepower, supplier, equipment specs, and more. The implementation of such a database facilitates plant management efforts on both sides – the designer and the client – as they can share and view current, up-to-date plant drawings and gain immediate access to a variety of information, such as how many times a valve or pump appears within the entire plant drawing set. By putting this technology and database to work as part of the P&ID Program, information is readily available and easily accessible, versus former methods that not only vary by plant, but also potentially involve a blend of electronic and paper drawings, hand drawings, and attempts to track down a long-time plant employee with the inherited knowledge to address a situation. Moving forward, when adjustments to plant processes or equipment are made, plant managers will ensure Clark Nexsen’s industrial team receives a copy, and our engineers will make the associated change within the smart P&ID and database – maintaining an accurate record for the future. In the long term, the P&ID Program provides a variety of benefits associated with efficiency, quality control, and improved process knowledge.