The existing two-lane 216’ long Centerville Turnpike Bridge over the Chesapeake and Albemarle Canal consists of a 168’ long non-symmetrical riveted steel swing span truss with a single 48’ long fixed approach span. The structure, constructed in 1955, was heavily deteriorated with reduced load posting and had been damaged by several over-height vehicle impacts.

The overall goal of this project was to provide a rehabilitated unposted structure capable of carrying legal loads which would remain operable for a 15-to-20-year lifespan while funding, design, permitting and construction of a high-level fixed overhead replacement structure is secured. Clark Nexsen served as the prime consultant for the project, providing overall project management, structural and waterfront/fender system design, and worked closely with a moveable bridge design subconsultant for the rehabilitation of the mechanical systems and the replacement of the electrical systems. The project also added an over-height vehicle detection system to improve safety. An as-built load rating of this complex structure was required, to include the truss gusset plates.  Design. The extent of the structure deficiencies were well known to the design team through numerous routine or interim damage inspections performed on the structure. To achieve the desired structural capacity and operational lifespan the following repairs were required:

Design. The extent of the structure deficiencies were well known to the design team through numerous routine or interim damage inspections performed on the structure. To achieve the desired structural capacity and operational lifespan the following repairs were required:

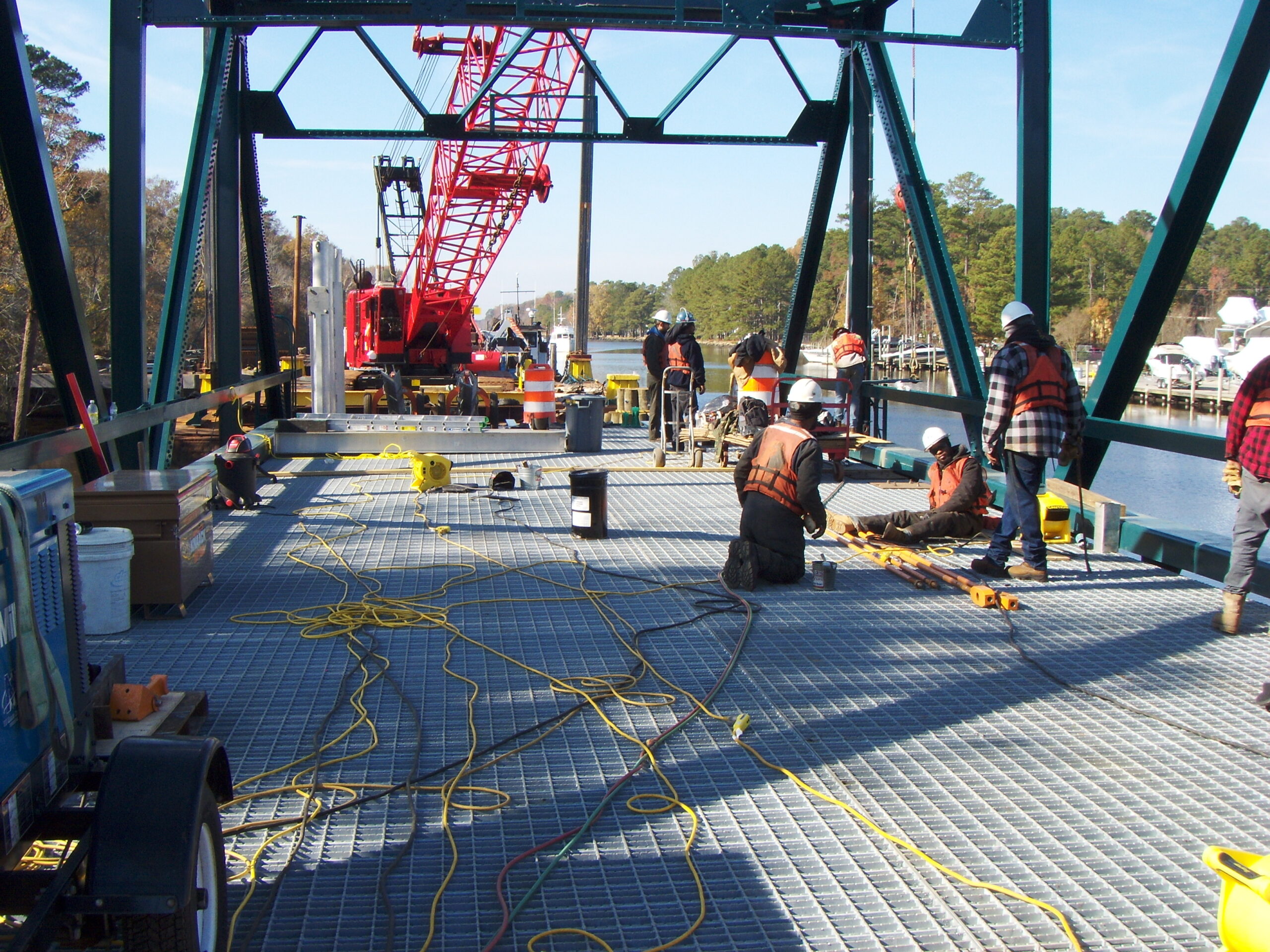

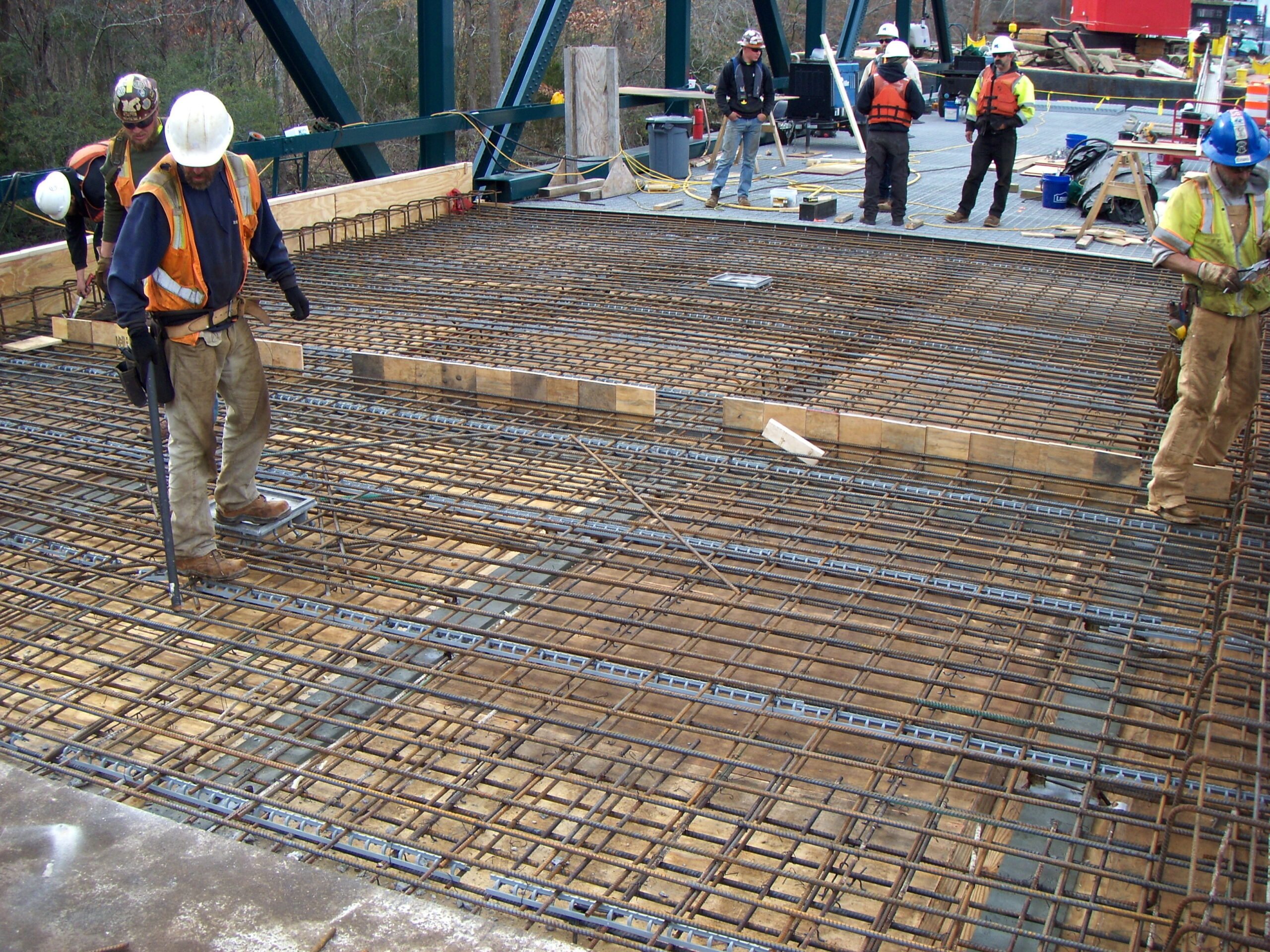

- Replace the Steel Grid Deck, Stringers, Approach Span Bearings, and a Portion of the Concrete Deck

- Replace Approach Span Deck Expansion Joint Seal and Install Epoxy-Sand Deck Overlay

- Construct Supplemental Rest Bents for Truss Jacking and Blocking

- Replace Timber Fender System and Jacket Timber Tender House Piles

- Replace Tender House HVAC System, Plumbing, Lighting, and Lightening Protection

- Replace Center Pivot Bearing, Turning Machinery and Support Framing

- Rehabilitate Wedge Machinery and Supports, Balance Wheels and Track

- Replace Motor and Relay Controls, Main Console, Conduits & Wiring, and Submarine Cables

- Install Over Height Vehicle Detection System, Bridge Roadway and Navigation Lighting

- Full Structure Recoating and Complex Rebalancing of Non-Symmetrical Truss.

Through the design effort, close attention was paid to provide constructible details which could be accomplished within the short full closure window and to organize work tasks which could be completed prior to or after the full closure. Despite the complexities of the delicate span rebalancing, the design team identified the opportunity to demo additional deck concrete to facilitate the bearing wedge drive and turning machinery replacement and then utilize lightweight concrete to extend the solid deck over the full extent of the machinery as well as to re-orient the stringer framing to provide a more robust layout less susceptible to corrosion. Improvements were also made to the fender system design to provide additional protection.

Satisfying the client’s objectives. In addition to providing project management and engineering to remove the maintenance headache that this structure had become for the City’s bridge crew, Clark Nexsen also successfully developed the State of Good Repair grant application to secure funds for over half of the full project cost.

Satisfying the client’s objectives. In addition to providing project management and engineering to remove the maintenance headache that this structure had become for the City’s bridge crew, Clark Nexsen also successfully developed the State of Good Repair grant application to secure funds for over half of the full project cost.

Challenge. Centerville Turnpike carries over 16,000 vehicles per day in each direction and is one of only five North – South crossings of the Chesapeake and Albemarle Canal throughout Chesapeake and Virginia Beach. The canal is part of the Atlantic Intracoastal Waterway and marine traffic had to remain intact. The extensive nature of the repairs required that the roadway remain closed to vehicular traffic for rehabilitation.

Solution. The design team developed an aggressive 12-month long repair plan where select components of the work could be completed during a 6-month full shutdown of the roadway with incentives for early completion. The 600-ton swing span truss was opened 90 degrees to allow unimpeded marine traffic and then jacked and blocked onto supplemental rest bents for the bulk of the repairs. Close coordination was held with the US Coast Guard, the Army Corps of Engineers operating the Great Bridge Locks and the Hampton Roads Maritime Association. Clear meaningful documentation of the project needs were communicated, resulting in modification to the opening schedule during final testing and select construction activities such and trenching for the new submarine cable and fender pile driving operations in the tight channel.

The design team also performed a corridor-wide traffic analysis utilizing existing data and modeling as well as updating select traffic counts to investigate peak traffic flow. Signal timing was optimized, and lanes adjusted at several intersections; however, the capacity was less than ideal. Working closely with the City, preventative paving and other maintenance operations were scheduled in advance of the work on impacted roadways and non-essential construction on these corridors was postponed. The design team supported the City Engineer with public presentations to City Council and HRTPO, as well as on the City website to communicate the anticipated impacts. The project was completed one month ahead of schedule and the full roadway closure was completed two weeks ahead of schedule.

Bonus Challenge. Three months following project completion, a marine accident occurred with a tug and fully loaded scrap steel barge impacting the truss while opening in the early morning hours of a Saturday in mid-November. Within the hour, before daybreak, Clark Nexsen’s project manager and lead bridge engineer met on site with the lead mechanical engineer, the Contractor’s project manager, and the City’s bridge operations engineer to assess the damage, which was extensive.

The following day, the team met onsite again and formed a partnership to repair the damage on an expedited basis. The team worked through the holidays, often 6 or 7 days a week to document the damage, develop repair sketches for early material procurement and cost estimating, followed by formal plans for documentation and construction. The bridge was fully jacked and blocked for evaluation and repair of damage to the center pivot bearing, full replacement of the end floor beam, and repairs to several stringers and fracture critical truss gusset plates.

The following day, the team met onsite again and formed a partnership to repair the damage on an expedited basis. The team worked through the holidays, often 6 or 7 days a week to document the damage, develop repair sketches for early material procurement and cost estimating, followed by formal plans for documentation and construction. The bridge was fully jacked and blocked for evaluation and repair of damage to the center pivot bearing, full replacement of the end floor beam, and repairs to several stringers and fracture critical truss gusset plates.

Significant repairs were also made to the mechanical system with work occurring to the bearings and driven wedges, the drive shaft pinion and support framing, rack, and track. The one-of-a-kind rack and track castings had to be carefully measured and custom made for replacement. All work was completed, and the bridge restored to operation within five months of impact. Full documentation of the damage was made both for evaluation and design as well as supporting the City with legal efforts through trial to recoup the cost of the repairs.

Significant repairs were also made to the mechanical system with work occurring to the bearings and driven wedges, the drive shaft pinion and support framing, rack, and track. The one-of-a-kind rack and track castings had to be carefully measured and custom made for replacement. All work was completed, and the bridge restored to operation within five months of impact. Full documentation of the damage was made both for evaluation and design as well as supporting the City with legal efforts through trial to recoup the cost of the repairs.