Reconciling Design Energy Models with Real World Results

Energy modeling is at the forefront of sustainability and high performance building design. A critical tool in the design process, the information it provides has the potential to help designers transform energy performance – but the assumptions that are inherently part of the process can put accuracy at risk. How do we make energy modeling more reliable? And how do we reconcile model projections with real world results? Clark Nexsen’s Brian Turner explores the benefits and challenges of energy modeling and discusses how design firms can implement standards for the highest possible accuracy.

No longer solely a social and ethical imperative to protect our environment, sustainable design and construction is in increasingly high demand for its ability to deliver more cost-effective solutions both in initial investment and long-term operations. With roughly 40 percent of total US energy consumption by commercial and residential buildings in 2015 (US Energy Information Administration), it is no surprise that building owners and operators are exploring ways to enhance energy performance. Relying on design criteria including energy codes, green building rating systems, and industry energy and carbon initiatives, owners are actively seeking solutions that will reduce their lifecycle operational costs by targeting a desired level of building performance.

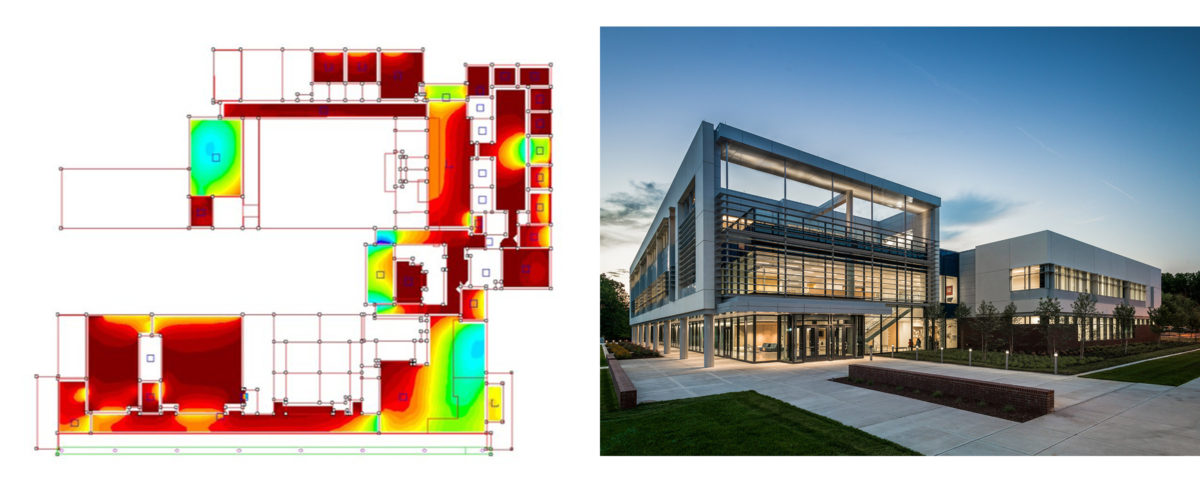

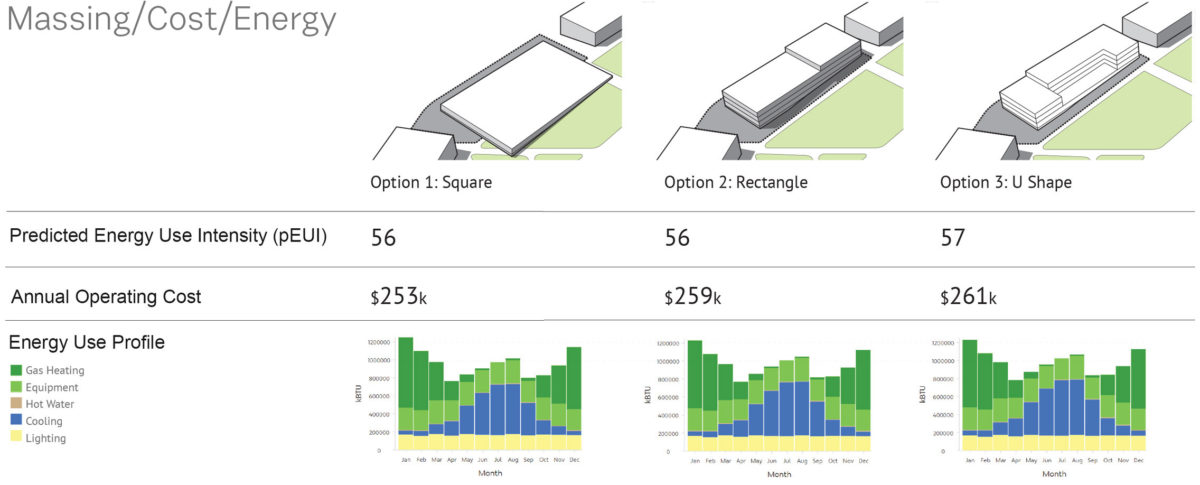

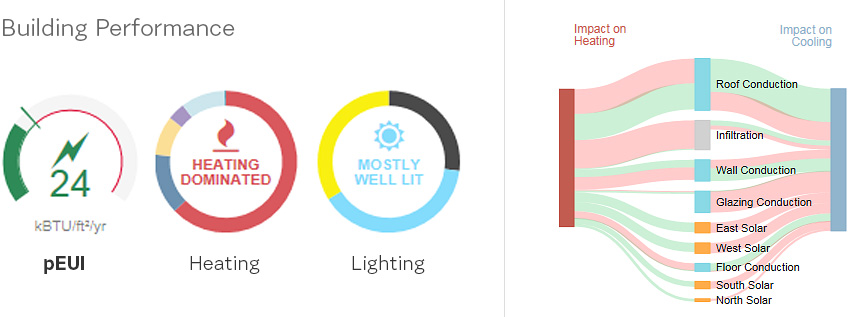

To evaluate the performance of future buildings and inform design decisions, designers leverage energy modeling to simulate the potential energy consumption of a building (or campus) and assess the ROI of green energy solutions. Taking into account items such as utility bills, lifecycle costs, air conditioning systems, lights, and hot water, the pEUI (predicted energy usage intensity) projected by these models plays an important role in helping clients and designers balance priorities and make informed decisions to develop the most efficient buildings possible.

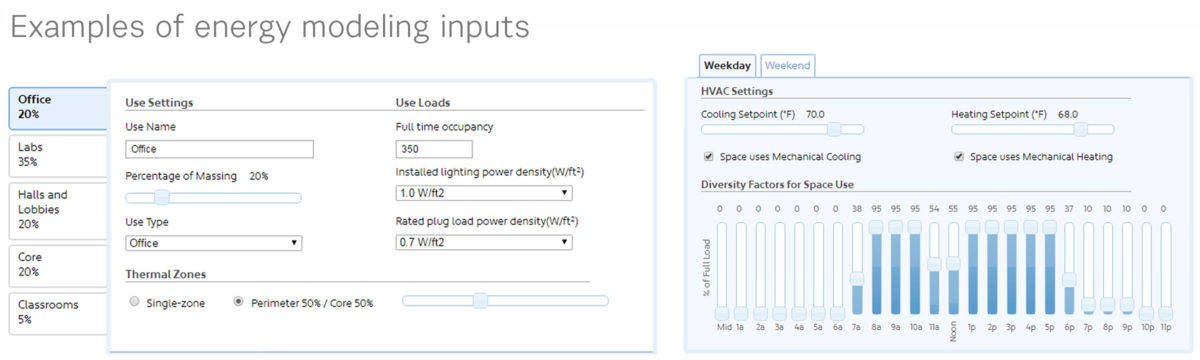

The energy modeling process, however, is not without challenges. As you might imagine, the inputs to an energy model are numerous and difficult to quantify with certainty during the design process. Often, these inputs include, at best, educated guesses: how many computers will be on at 3pm on June 28th, and how much power do they consume? How often will the conference room be used, and at what level of capacity? Do the building occupants travel often, or telecommute? Energy models generate very specific outputs synthesized from hundreds—perhaps thousands—of educated assumptions and approximations of how the building will actually perform.

But in the real world, the occupancy and maintenance of a building can impact energy use significantly – regardless of projections and design intent. A 2011 study by the New Buildings Institute concluded that the occupancy and operation of a building can “increase building energy use from 80-140%, or conversely reduce energy use by about 30% in comparison to the typical baseline building.” Representative of the potential inaccuracies in the modeling process, this wide variation highlights the importance of close collaboration and communication between the client and design team to establish inputs that will be as close as possible to real use.

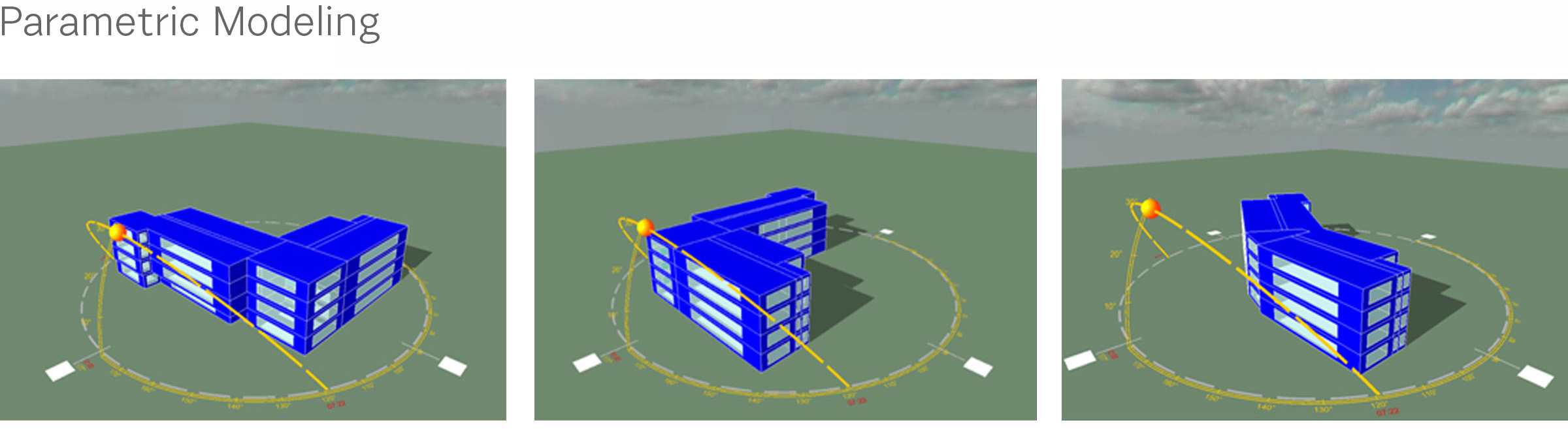

The potential variation between energy modeling and real world results also leads us to the billion dollar question: with all of this uncertainty, are energy models useful? Put simply, yes. The best use of a design phase energy model is to inform design decisions, not predict energy consumption with certainty. For example, parametric modeling can be used to determine optimal U-values, shading coefficients, glazing configurations, massings, and temperature setpoints. Energy models can also be used to explore engineering system alternatives and study the relative impacts of energy conservation strategies. Comparative modeling can inform decisions about where to invest construction dollars based on lifecycle performance. It may be helpful to think of the results of an energy model as analogous to the EPA fuel economy sticker on a new car: the actual miles per gallon of the car will vary from the EPA sticker value, but the relative performance between vehicles is accurate and can inform the decisions of both the car buyer and the car designer.

Additionally, there are steps designers can take to improve the accuracy of design phase energy models:

- Energy modelers should be certified to demonstrate their proficiency in the practice. Certification programs such as the Building Energy Modeling Professional (ASHRAE) and Building Energy Simulation Analyst (AEE) help to document competency in building physics and the computational methods used to accurately model energy performance.

- We must leverage energy models as an iterative tool throughout the design process – not using them only once at the beginning, or worse, once at the end, but multiple times to compare and contrast scenarios and maximize the owner’s initial investment as well as long-term costs. Using modeling as a tool to inform decisions throughout the design process provides continuous feedback to the model and improves the quality of its inputs.

- All energy models should be subject to a quality control review to check inputs and modeling methods and scrutinize the quality of the results.

- Energy modelers can and should continually enhance their knowledge of how buildings actually function—and sharpen their modeling skills—by participating in hands-on activities in buildings such as retrocommissioning.

- Finally, discussing the purpose and accuracy of a design phase energy model with the building owner and relevant stakeholders helps develop a mutual understanding of the benefits and limitations of the model. Additionally, including building users and operators in the design process will strengthen the quality of model inputs and provide the most accurate results.

In summary, to develop efficient, high performing buildings that deliver on client objectives and reduce carbon emissions, designers must thoughtfully integrate energy modeling throughout the design process. By holding ourselves to a high standard and understanding the inherent limitations of energy modeling, we can maximize design opportunities and provide the most efficient solutions for our clients.

Brian Turner, PE, CEM, BEMP, initially presented Reconciling Design Energy Models with Real World Results at the World Energy Engineering Congress. To learn more about energy modeling and building performance or to speak with Brian, please call 757.455.5800 or email bturner@clarknexsen.com.